EXPERTISE RESOURCES: Central metallurgy laboratory

STAINLESS Group has an expertise laboratory of more than 40 m2 equipped with a range of machines dedicated to carrying out metallurgical analyses. It includes almost twenty pieces of equipment, such as an OES spectrometer, polishing machines, hardness testing machines, a laser micrometer, an oven, a tube furnace and an optical microscope.

Backed by almost 100 years’ experience and close collaboration with the main materials producers, we offer our current and future customers standard or customised training courses. These courses are run by our Technical Director and Doctor of Metallurgy, Thierry Turpin.

Adapted to the specific needs of manufacturers, these courses are aimed at a wide range of audiences, from lay people to buyers, design offices and R&D departments.

OUR CENTRAL METALLURGY LABORATORY IS EQUIPPED WITH A NUMBER OF EXPERT ASSESSMENT FACILITIES:

We have state-of-the-art equipment for testing raw materials as part of the development of new materials, as well as for testing customer parts to quickly identify the source of any problems encountered.

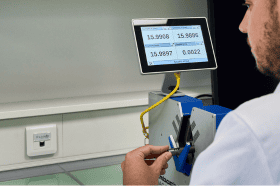

Laser micrometer

Read more

Our laser micrometer gives us precise control over the diameter and ovality of our bars, enabling us to meet our customers’ most exacting requirements.

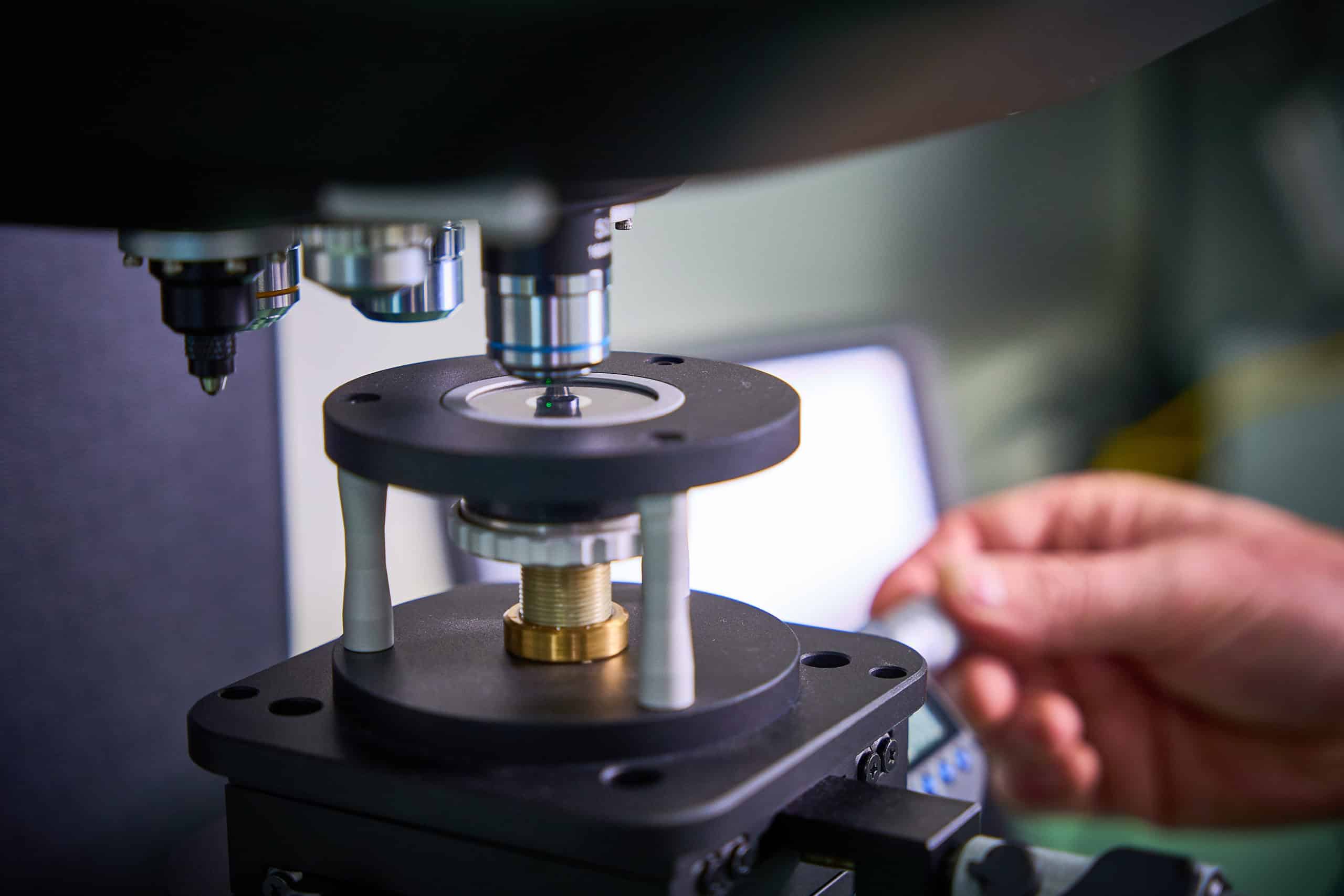

Optical microscope

Read more

Our preparation equipment, such as the cut-off machine, automatic polishing machines and etching fume cupboard, reveal the microstructure, which is observed with our optical microscope offering magnifications of up to 1,000 times. This equipment is essential for analysing the microstructure (grain size, identification of the phases present, inclusional cleanliness, etc.).

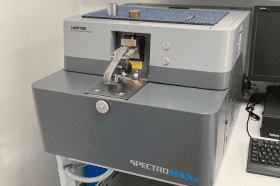

Spectrometer OES

Read more

The chemical composition of our products is verified by our OES spectrometer, with accuracy down to a few ppm. The sparks produced during the test emit light radiation characteristic of each atom. The spectrometer can thus identify and measure the chemical elements present in the alloy after calibration against reference standards.

Struers hardness testing machines

Read more

Our Struers hardness testing machines enable us to complete our expertise by measuring the hardness of alloys. Micro-hardness is preferred for local analyses or small samples, while macro-hardness (HBW, HRC or HV) is used to determine the overall hardness of the sample. Both machines produce an indentation whose dimensions depend on the hardness of the material.

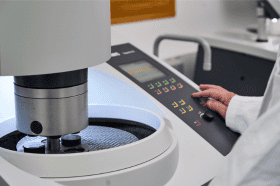

Polisher

Read more

The automatic polisher allows the recording of pre-defined methods, adapted to each grade, guaranteeing reproducibility of sample preparation from one expertise to another.

Oven

Read more

In addition, to check the response to heat treatment of certain grades, ageing can be carried out using an oven at temperatures of up to 650°C. The response to heat treatment of certain alloys (17-4PH, 1.4543, 1.4614, etc.) hardened by precipitation of intermetallics is thus evaluated as a function of the ageing temperature.

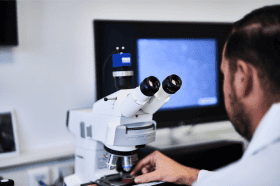

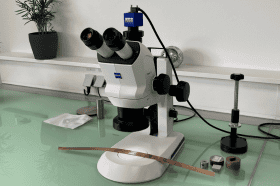

Binocular magnifier

Read more

For metallography and fractography, we use a binocular magnifying glass to examine aspects such as fracture surfaces in detail.